Extrusion of aluminium profiles

Aluminium extrusion is the process of transforming a cylindrical raw material, called a billet, into a specific profile.

In this mechanical process, the aluminium billet is heated to high temperatures until it becomes malleable.The malleable aluminium is then pushed through a mould, known as a die, by a piston to form a profile with a specific cross-section.

After extrusion, the profile undergoes cooling, cutting, and stretching to achieve the desired rigidity and strength.

Extrugasa extrusion presses

Capacities and measures

- Number of Extrusion Presses: 6

- Types of presses: 1,300, 1,600, 2,000, 2,500, 3,200 and 4,800 tonnes.

- Maximum profile extrusion length: 17 m.

- Weights: between a minimum of 0.1 kg/m and a maximum of 45 kg/m.

- Annual production capacity: 40,000 Tn.

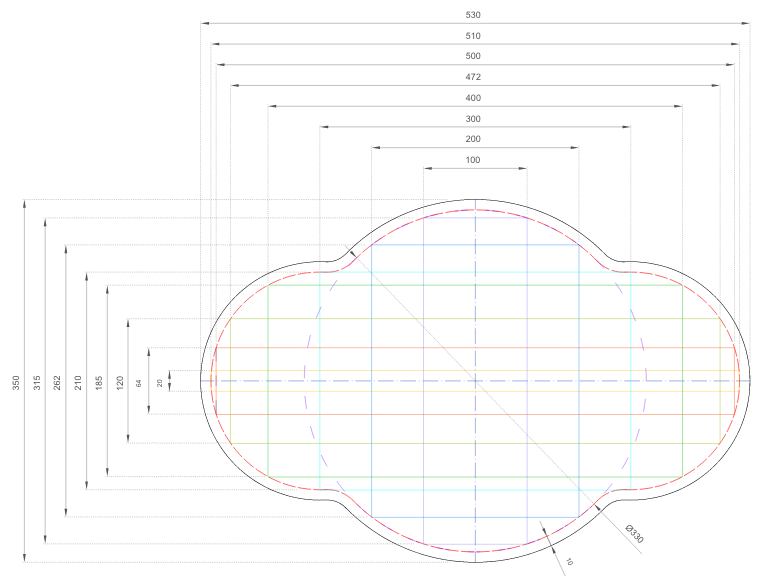

- Extrusion profile sizes:

European regulations

- Extrusion process according to EN 755-9 EN and EN12020-2

- Development of mechanical properties according to EN 755-2

Aluminum Alloys

Depending on the type of project or purpose of the profile, we work with various alloys that allow us to reinforce the properties of aluminium:

6060, 6063, 6005A, 6061 and 6082.

Heat treatments

- T4, T5, T6, T66

Raw material

Extrugasa offers different types of aluminium billets, the raw material with which we extrude the profiles:

Fénix:

- Our certified recycled aluminium billet manufactured in our foundry from 99.9% aluminium scrap.

Primary Billet:

- Conventional aluminum billet.

- Primary aluminium billet with a low carbon footprint: made from renewable energies with values below 1/4 of the global average.

Matrix service and testing extrusion

Extrugasa offers the die manufacturing service. Once the project has been approved by the client and technical office, the order for the matrix is placed, which is prepared in collaboration with our suppliers.

To verify the proper functioning of the die in extrusion, the laboratory generates dimensional tests of the profile in 2D , checking that the dimensions marked on the plane correspond to the extrusion.

Quality certificates

- ISO 9001: for quality management system.

- ISO 14001: for the implementation of an environmental management system for production processes

- CE marking certificate, on request.