Home > Trespa

Trespa

Aluminum in team with Trespa

Extrugasa, in order to improve the thermal insulation of buildings, we have spent almost a decade developing together with Trespa its own ventilated facade systems to achieve greater efficiency, working an attractive aesthetic from an infinite number of designs.

Functionality of the ventilated facade

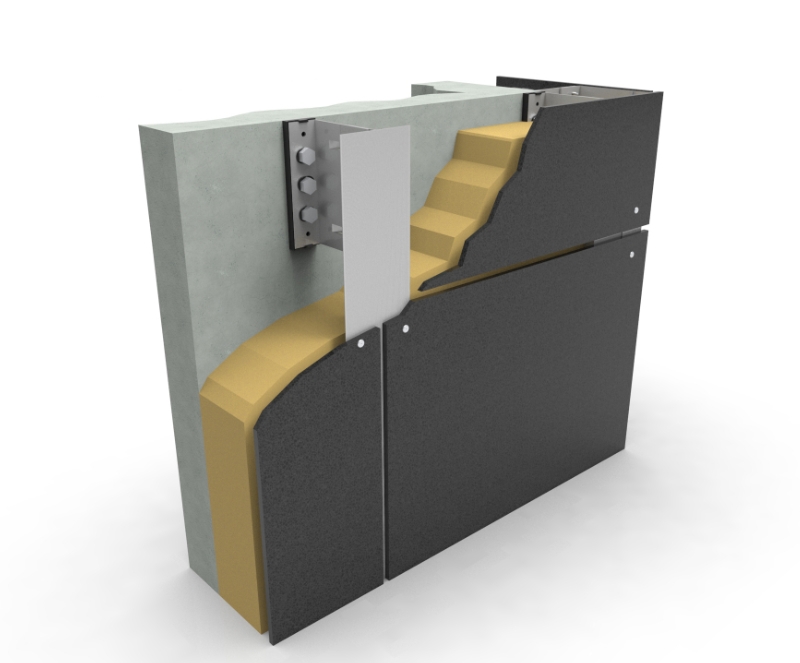

The ventilated facade is an exterior cladding system that is installed by means of fixings and anchors, in new buildings or in the renovation phase, to create a barrier between the interior and exterior of the structure and to regulate the exchange of heat, air and light, achieving thermal and acoustic insulation. Thus, Extrugasa’s systems are composed, from inside to outside, of the following parts:

- Load-bearing wall, which supports the weight of the cladding and the stresses it transmits.

- Substructure and anchorage, which transmit their stresses from the cladding to the building structure.

- Insulation, which is installed on the exterior of the wall to improve expansion and contraction performance.

- Semi-permanent membrane, which is installed behind the insulation in cases where moisture seeps through it.

- Air chamber or ventilation between the insulation and the sheathing that allows constant air circulation.

- Exterior face cladding that responds to the appearance of the façade.

From Extrugasa

Extrugasa participates in the manufacture of its exterior panels, so that we jointly develop versatile ventilated facades that enhance buildings and acquire an exceptional aesthetic thanks to the possibilities in terms of designs and manufacturing formats, in addition to a wide range of colors and assembly.

Thus, in the installation process of ventilated facades with Trespa panel and aluminum substructure of Extrugasa, different types coexist:

- TS700 Riveted System

- TS700 ADH System

- TS200 System

- TS300 System

In Extrugasa we take care of the extrusion of aluminum profiles for the installation of Trespa’s own ventilated facade systems.

Facade fastening anchors

Depending on the type of hanging used, specific anchors will be used to fix the facade and connect the system to the base material to transmit the loads. In this way, each system can be installed in a different way.

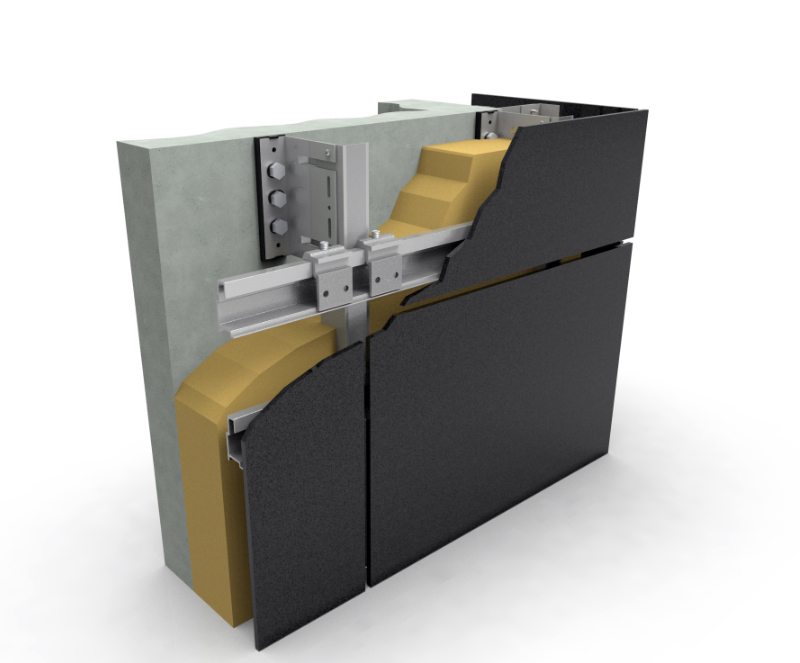

TS-700 Riveted System

The panels are anchored by rivets to the vertical L- or T-shaped profiles, which are in turn anchored to the facade by means of aluminum brackets.

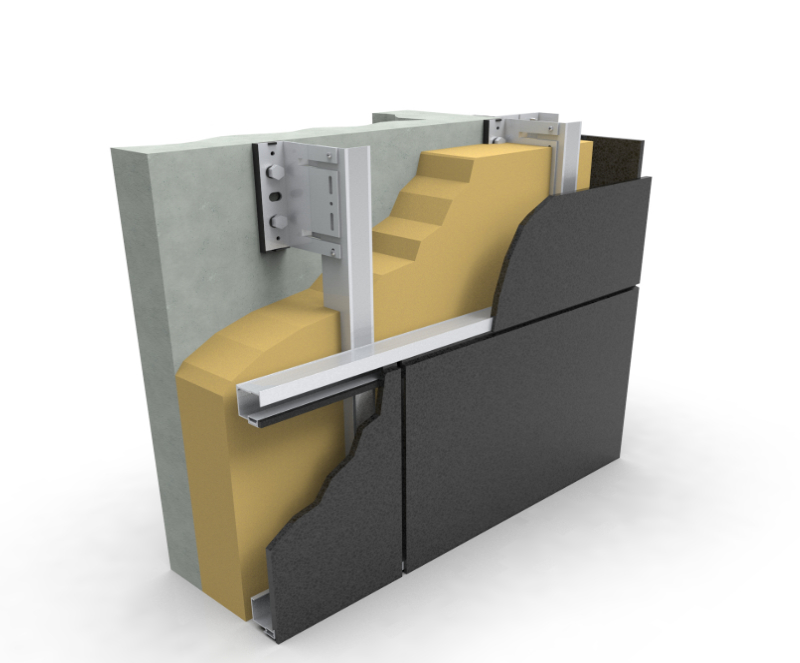

TS200 System

Concealed fixing is by means of clamps screwed to the back of the panel which are hung on a special horizontal profile which in turn is fixed to the vertical L- or T-shaped profiles and their corresponding brackets.

TS300 System

Concealed fixing, the support and fixing of the panels is done on horizontal profiles, which are screwed to the vertical L or T-shaped profiles, which are in turn anchored to the facade by means of aluminum brackets.