Home > Our history

Our History

1963

Our first contact with aluminum

We do it as a supplier and manufacturer of aluminum windows, a material that we bet on and that few knew about.

1977

First anodizing plant

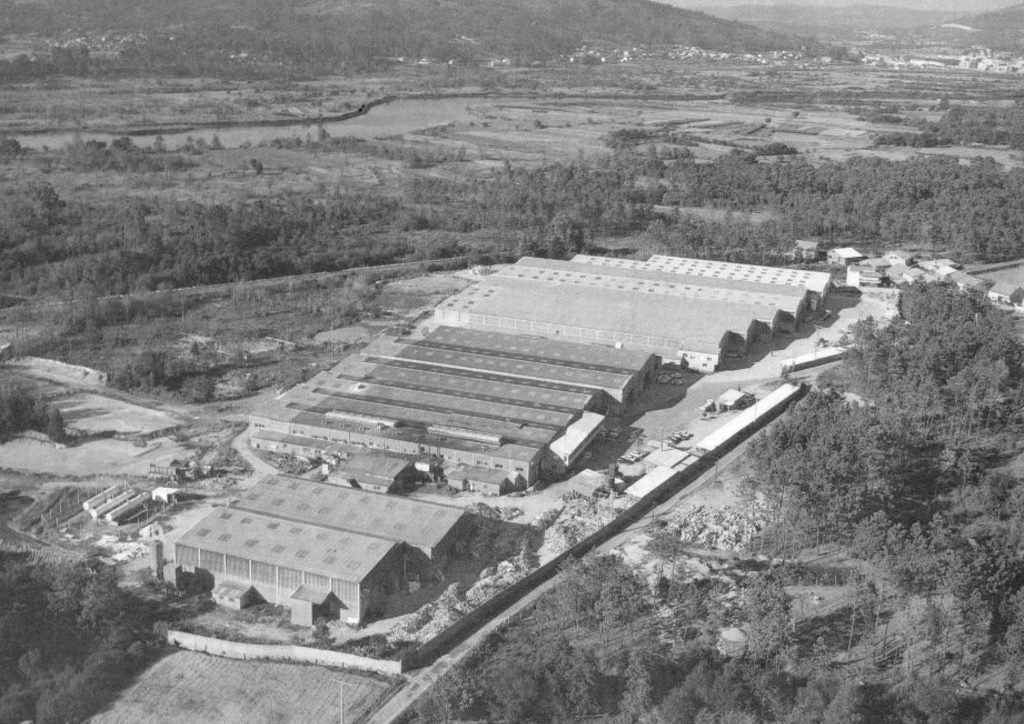

With it, we are located in Valga, where our headquarters are located and where we centralize all our production processes.

1981

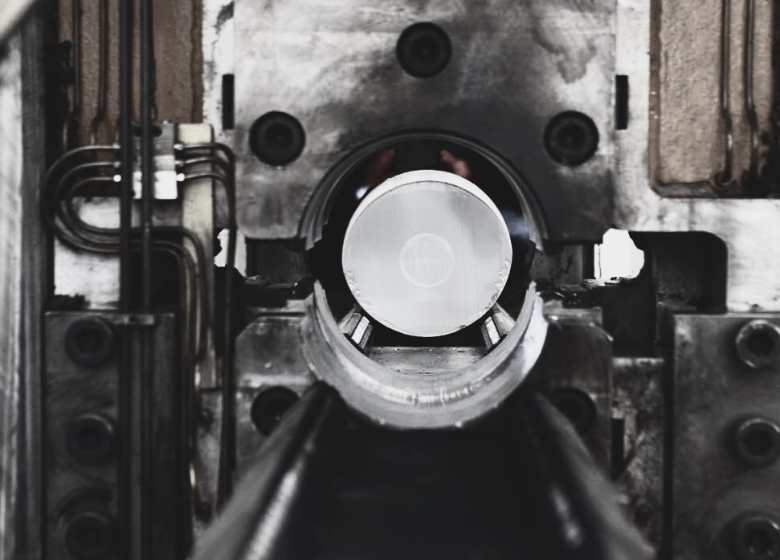

We start with extrusion

We went from being suppliers to manufacturers of aluminum profiles, expanding our market to the industrial sector.

1982

First powder coating plant

We added this new service to expand the range of finishing options for our customers’ projects.

1984

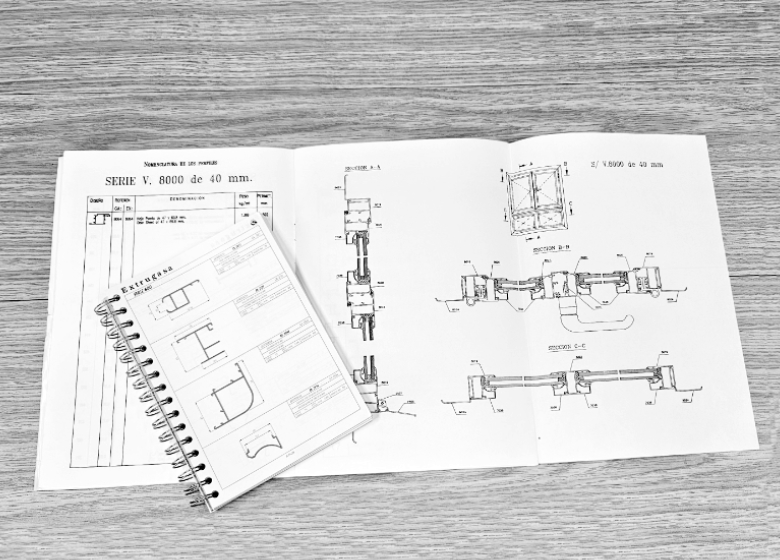

We developed our first own aluminum carpentry systems.

From our technical office, the first designs of practicable, sliding and curtain wall opening systems are made.

1994

Changing the concept of our systems with the Termal break

Adapting to market demands and expanding a new polyamide assembly service for carpentry systems.

1995

We start exporting

We leave the peninsula and enter the international market. With this, we began to strengthen the industrial market and adapt logistics.

1999

We specialize in industrial sectors.

Thanks to the acquisition of the first machining centers, we are able to offer our customers a complete production cycle, which allows them to obtain a finished solution.

2000

First sustainable action:

the WWTP

We installed a Wastewater Treatment Plant for the treatment of water used in all our production processes.

2005

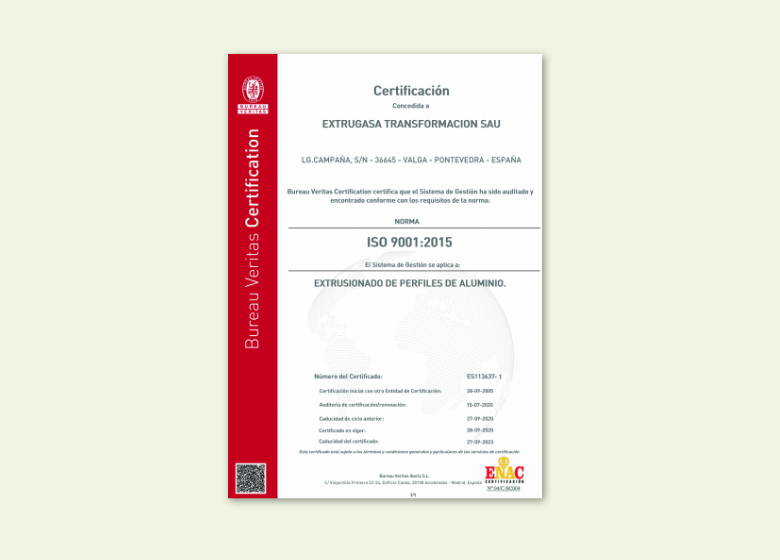

Implementation of ISO - 9001

Standard that certifies the aluminum profile extrusion management system.

2014

Quinarq is born

A product range designed and developed with

the conceptualization of standardization and

industrialization for carpentry systems.

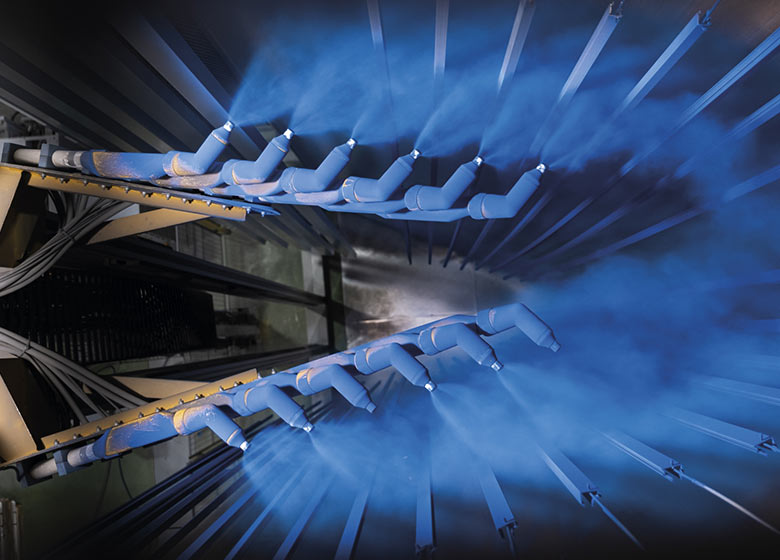

2015

The 14 meters

Due to the high demands of our customers,

We adapt all production processes to this

extrusion, from extrusion, surface finishing,

and adapted logistics.

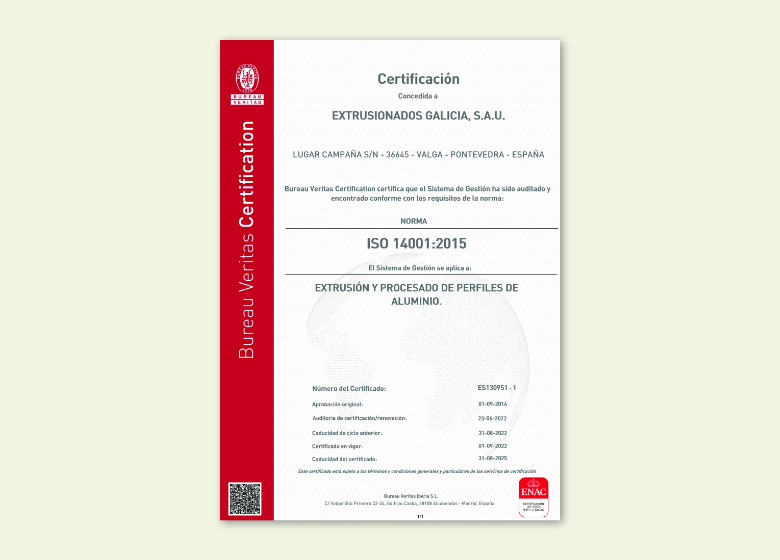

2016

Implementation of ISO-14001

Standard that allows the implementation of an environmental management system for production processes.

2023

We cover 30,000 m2 of our infrastructure with solar panels.

Self-consumption installation that generates up to 25% of the company’s energy demand and allows us to reduce CO2 emissions.

2024

The ultimate expression of recycling, smelting and casting. Fenix

With this aluminum recycling service we close the production circle and generate a sustainable product, Fénix, our recycled billet made from 99.9% aluminum scrap.

Our Track Record

Our first contact with aluminum

We do it as a supplier and manufacturer of aluminum windows, a material that we bet on and that few knew about.

First anodizing plant

With it, we are located in Valga, where our headquarters are located and where we centralize all our production processes.

We start with extrusion

We went from being suppliers to manufacturers of aluminum profiles, expanding our market to the industrial sector.

First powder coating plant

We added this new service to expand the range of finishing options for our customers' projects.

We developed our first in-house aluminium joinery systems

From our technical office, the first designs of practicable, sliding and curtain wall opening systems are made.

Changing the concept of our systems with the Termal break

Adapting to market demands and expanding a new polyamide assembly service for carpentry systems.

We start exporting

We leave the peninsula and enter the international market. With this, we began to strengthen the industrial market and adapt logistics.

We specialize in industrial sectors

Thanks to the acquisition of the first machining centers, we are able to offer our customers a complete production cycle, which allows them to obtain a finished solution.

First sustainable action: the WWTP

We installed a Wastewater Treatment Plant for the treatment of water used in all our production processes.

Implementation of ISO - 9001

Standard that certifies the aluminum profile extrusion management system.

Quinarq is born

A product range designed and developed with the conceptualization of standardization and industrialization for carpentry systems.

The 14 meters

Due to the high demands of our customers, we adapt all production processes to this measure, from extrusion, surface finishes, machining and adapted logistics.

Implementation of ISO-14001

Standard that allows the implementation of an environmental management system for production processes.

We cover 30,000 m2 of our infrastructure with solar panels.

Self-consumption installation that generates up to 25% of the company's energy demand and allows us to reduce CO2 emissions.

The ultimate expression of recycling, casting and Fénix

With this aluminium recycling service we close the production circle and generate a sustainable product, Fénix, our billet recycled from pre- and post-consumer scrap.